Breakthrough in microLED development: Red pyramidal microLED based on the same material as green and blue

Linköping, Sweden, 2024-12-18

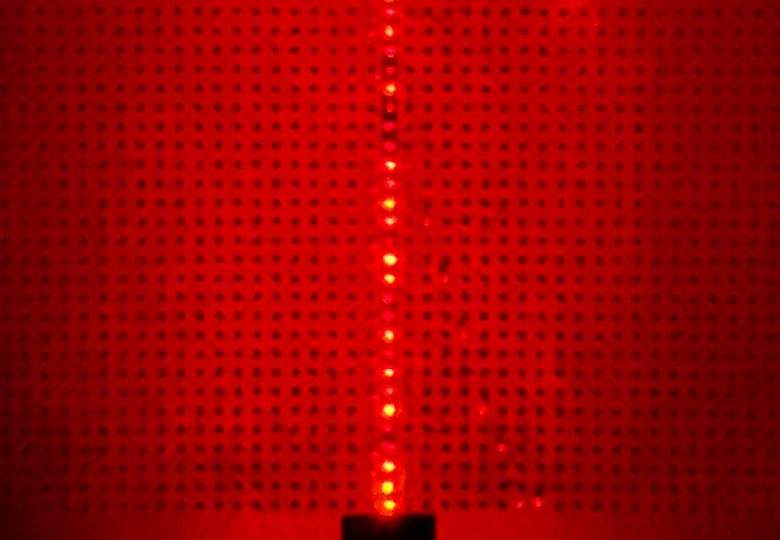

In a remarkable breakthrough in their research, Polar Light Technologies has achieved red light of 625 nm based on the company’s non-etching bottom-up concept. This means Polar Light Technologies have reached red, green, and blue pyramidal microLEDs using the same material compound.

The pyramidal design has the ability to be manufacturable while maintaining excellent microLED performance, laying the foundation for monolithic RGB displays.

This milestone marks the culmination of years of rigorous research and development, truly enabling spatial computing and next-generation panel displays.

Red without compromise

Blue and green MicroLEDs have been in the market for years, but reaching a red colour has been difficult due to fundamental challenges in the material properties. There are several workarounds or alternatives for reaching a red colour, but they all come with some compromises, such as efficiency, manufacturability, or the need to integrate with other material systems.

“Pursuing Polar Lights’ innovative pyramidal LED concept has been about overcoming those challenges without compromises. Today, thanks to a great tech team, we have succeeded in realizing the red-emitting microLEDs based on our innovative pyramidal structure”, says Lisa Rullik, CTO of Polar Light Technologies.

Unique pyramidal structures

Polar Light Technologies’ microLED is composed of pyramid shapes that are built with a novel bottom-up approach, a technology that comes with unique benefits:

- The inevitable strain in the lattice-mismatched InGaN/GaN structures is reduced, which is important to be able to manufacture blue, green, and red microLEDs with the same material system, that is, to build monolithic RGB.

- It gives a unique possibility to integrate the frontplane with a backplane

- No etching is needed, which means:

- Performance is maintained also for smaller dimensions since no etching damages occur

- Enables even sub-µm LEDs – nanoLEDs

- Easier to manufacture and integrate with CMOS and TFT

- Narrow emission cone: Lambertian light lobe from the emitter, which is important for microprojectors

With these unique benefits, the microLED from Polar Light Technologies solves key challenges in bringing the technology to the market.

Performance, manufacturability and nanoLED

Polar Light Technologies’ same-compound-based microLED offers high performance and excellent manufacturability. Its very small dimensions and narrow emission cone further enhance the offer. The technology also opens up for nanoLED applications – as soon as the rest of the display technology catches up.

“Our technology addresses microLED challenges in a way that has never been done before,” says Oskar Fajerson, CEO of Polar Light Technologies. “Now we’re moving towards commercialization of this groundbreaking technology, focusing on putting products on the market.”

About Polar Light Technologies

Polar Light Technologies has developed a novel bottom-up approach for manufacturing pyramidal microLEDs using controlled crystal growth, atomic layer by atomic layer. This eliminates the top-down destructive etching used by competitors. The result is unmatched pixel size, brightness and energy efficiency. The company has its roots in long and unique research done by Professor Per-Olof Holtz and his research team at Linköping University, with support from Vinnova, Sweden’s innovation agency.

For more information

Oskar Fajerson, CEO of Polar Light Technologies

Telephone: +46 738 19 38 00

oskar.fajerson@polar-light-technologies.com

Lisa Rullik, CTO of Polar Light Technologies.

Telephone: +46 760 21 34 80

lisa.rullik@polar-light-technologies.com

Per-Olof Holtz, founder of Polar Light Technologies and professor at Linköping University

Telephone: +46 708 75 26 28

per-olof.holtz@polar-light-technologies.com