600 million bright and effective pixels on the area of your thumb

With a technology born from unique research, Polar Light Technologies develops the next generation of microLEDs. The minimal pyramidal structure translates into a more efficient, less energy-consuming, and better-performing LED technology. The patented innovation is a key enabler for a great variety of light-demanding applications. With that, we position ourselves as a leading player in the young yet rapidly growing microLED market.

Various kinds of LEDs are used in modern technology. They exist in everything from our phone screens to our lamps. All of these LEDs come with great advantages but also some downsides. There are two dominant technologies today – OLED and QLED. OLED is a frequently used LED made from organic materials where each pixel can be controlled individually, creating high precision. In addition, a high blackness can be achieved, which is important for creating a good contrast and color reproduction. However, an OLED can cause a so-called burn-in, i.e. traces of the image that remain visible for a long period of time. The organic material means that the OLED is not robust, which in turn can lead to degradation where the light intensity becomes worse over time. QLED (Quantum LED) is based on traditional LCD technology where quantum dots are used to achieve better color reproduction and brightness. Since the quantum dots are not self-luminous, a background light is used to shine on them, and thus light is generated. It is therefore not possible to control the pixels individually, creating a limitation for the resolution.

MicroLEDs are the next generation of light-emitting diode technology. Compared to other LEDs, microLEDs are more energy-efficient and bright, they have a higher color saturation and longer lifespan. Their micrometer size also means they are much smaller – an important feature that makes the microLED a key enabler for various optical applications.

“MicroLEDs are a kind of hybrid between OLED and QLED where you can achieve the good qualities and at the same time eliminate, or at least reduce, the negative ones. You can have individual pixel control, achieve amazing contrast and exclude burn-in”, says Per-Olof Holtz, CSO and founder of Polar Light Technologies.

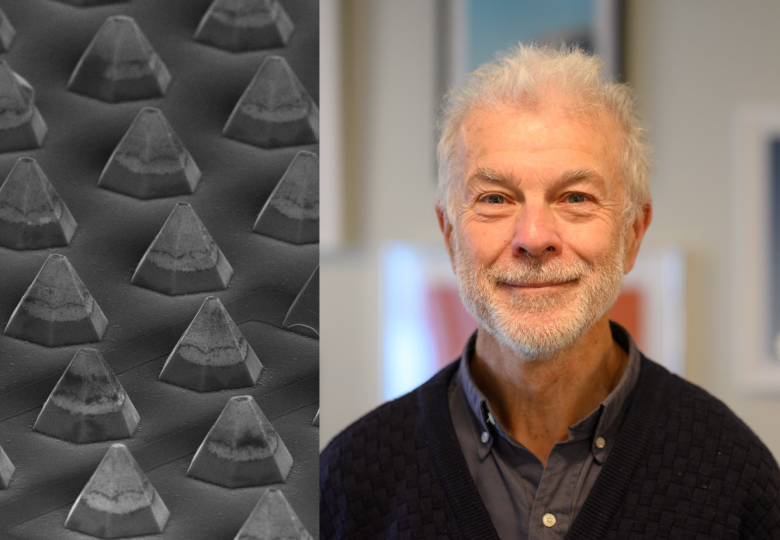

Polar Light Technologies develops a bottom-up microLED with unmatched pixel size, brightness and energy efficiency. The company has its roots in long and unique research done by Professor Per-Olof Holtz and his research team at Linköping University. It all started in 1997, when Holtz was a postdoctoral researcher in Santa Barbara, California. He became interested in learning about quantum dots and started doing research on them together with his team. Quantum dots are a zero-dimensional structure that has restrictions in all directions, meaning that electrons can be locked into them without the possibility of getting out. The first forms of quantum dots Holtz’s team studied had a spontaneous formation, which meant that they could not control where the quantum dots would form or what the density would be. In addition, there were very limited opportunities to decide their size. In 2008, after many years of research in the field, they had an idea that would allow them to determine the exact position of the quantum dots. This was done by creating micrometer-sized holes on a thin film that was inserted into a MOCVD reactor. Various gasses were then introduced into the reactor, creating a chemical reaction in which an ordered pyramidal structure of crystals grew in the tiny film holes.

“By placing the holes exactly where we wanted the quantum dots, we could get them with a particular density and with different sizes depending on the size of the holes”, Holtz says.

In 2011, Holtz and his team changed the shape of the top of the pyramid from round to oblong. This was done by creating a pyramid that no longer consisted of equal sides but had an asymmetrical structure. An important discovery was then made where the light emitted from the new pyramids came out polarized. Holtz and his research team realized that the discovery could mean great opportunities and translate into new applications in the semiconductor market. They decided to submit a patent for the discovery which was granted in 2014. Polar Light Technologies was then formed, and the patent was brought into the company.

“Today, our pyramidal LEDs are used for display and AR applications, which is a rapidly growing market where we want to be involved and influence. However, polarized light is something we will return to later. We are very proud of the patent because it enables many great applications and it is something that we want to develop and work with in the future”, says Holtz.

About 90 percent of all microLEDs on the market today are manufactured using a top-down process. In the process, quantum wells are used, and you want to make these as small as possible to achieve the desired effect. This is done by etching where all the material around the quantum well is removed, creating an “island” in the etched structure. This is a very rough method which always creates some level of damage to the edges. The smaller you make these structures, the more destructive the damage becomes as surface area in relation to volume increases the smaller the structure is made. Polar Light Technologies instead uses a bottom-up method where microLEDs are grown from the bottom and up, creating the company’s signature pyramidal microLEDs. It is the same process that Holtz and his research team used back in 2008, growing them from tiny holes in a thin film, atomic layer by atomic layer, using epitaxy. The manufacturing method is significantly more gentle than top-down, giving the microLEDs perfect surfaces without any damage. This is a very important quality of the LEDs as damage to them is fatal for optical applications. To generate light, electrons with negative and positive charge barriers are needed. If there is damage to the LEDs the charge barriers will be absorbed by them, and thus light will not be generated. The bottom-up process also allows the density and position of the microLEDs to be controlled as well as the size. Polar Light Technologies technology has a 1 000 times higher pixel density than existing technology. The microLEDs can reach a pixel size of one micrometer, or potentially even less, which is equivalent to more than 600 million bright and effective pixels on the area of your thumb. The pyramidal geometry also offers several advantages. One of them being that the integration of the backplane and frontplane can be done in a very favorable way. Another important advantage is the possibility of maintaining higher efficiency even at lower wavelengths, enabling efficient RGB-light.

“Today we can make blue LEDs that have a high efficiency, but when you move towards higher wavelengths it becomes increasingly difficult because you get built-in voltages in the material. With the geometry that our pyramids have, you have the possibility to control the built-in voltage. In turn that means there is the possibility of going towards higher wavelengths – that is towards green and red light with a maintained high efficiency”, says Holtz.